Title:

Liquefied (bio-)gas as a driving force for development and use of green energy technology

Description:

For an industry-oriented economy, a qualitatively and quantitatively reliable supply of energy is a high priority. However, energy transition requires accelerated use of regional resources. This implies the diversification of energy sources and use of all existing potentials. In the global network of economic structures an independent power supply is becoming increasingly significant, even at the expense of a higher cost of energy.

A more intensive use of alternative fuels makes a significant contribution to improving environmental performance. But this raises a technical challenge associated with the energy transition, which is the storage and distribution of high energy volumes, for example in the form of liquid biogas or natural gas. This is a specific technological issue that the project will address, jointly developing solutions and creating a technical/technological platform for a broader and more universal use of (bio-)LNG in a micro / nano form (e.g. in decentralised energy supply system) as an alternative fuel in the future. Thus, to cover all necessary aspects, the project’s content is divided into two parts. First focus on creating a cooperation space necessary for interaction between focal actors, accelerating development and use of (bio-) LNG technology, products and services in the micro and nano scale. The second part is presenting possible applications of the (bio-)LNG-based technology to raise awareness about added value of (bio-) LNG related technical solutions and to increase knowledge about their practical contribution to strengthening environmental sustainability and economic innovation of the South Baltic region. These applications include:

- Development and establishment of a (bio-)LNG station for refuelling boats

- Conversion of a small ship towards using (bio-) LNG as fuel

- (Bio-)LNG solution for a decentralised energy supply system for buildings

- Development and establishing of the (bio-)LNG station for refuelling locomotives

Quasi-static strength analysis of a ship retrofit with LNG-Tank

As part of work package 3.2: “Preparation of analysis presenting types of small-ships in use for conversion to LNG usage”, the University of Rostock developed and published several topics on the conversion of small ships to LNG. The students then had the opportunity to choose one of these topics for their study or even bachelor thesis. One of these topics was the retrofitting of a pilot ship with LNG tanks. Here, the University of Rostock was supported by the Lotsbetriebsverein e.V. (Kiel branch office). They provided the technical document of their Swedish pilot boat and declared their interest in the result of this study work. The author of the work is Mr. Joachim Foedtke, a student from University of Rostock.

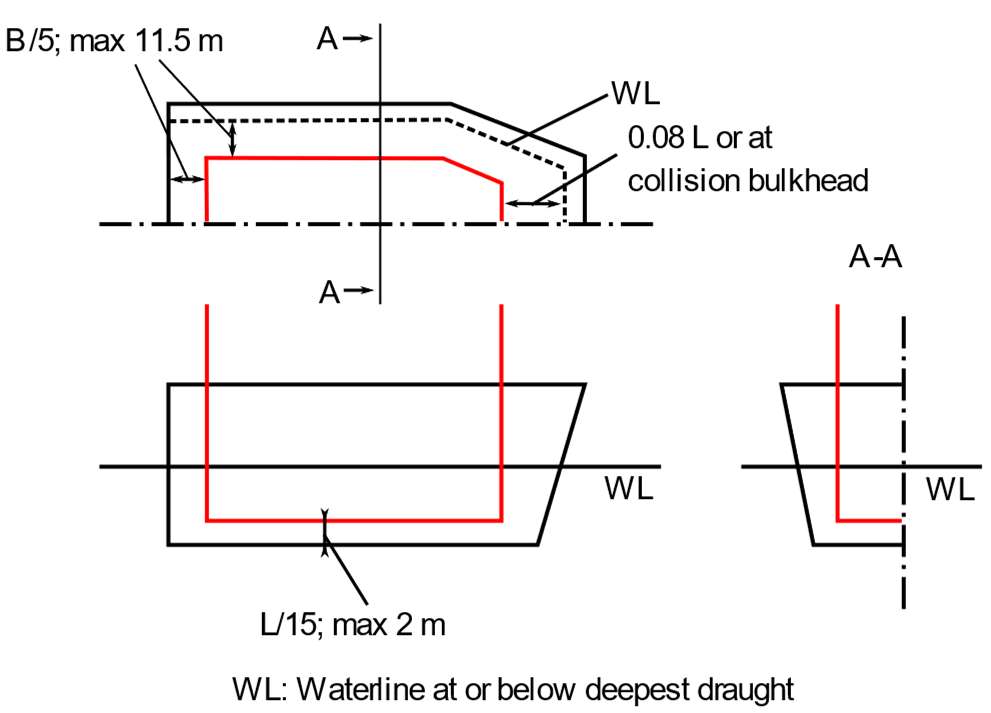

Due to the characteristics of LNG, there are several risks for ships. The low temperature can cause brittleness, vaporization and thus expansion due to heat, and lastly, the gases can form an explosive atmosphere if they mix with air. Therefore, it is important to ensure the safety of the entire LNG storage system. One of the most important regulations for LNG on ships is the IGF Code for ships using gases or other low-flashpoint fuels. This specifies the types of tanks that may be used on ships, the minimum distances that must be maintained from the ship’s hull and how to categorize the spaces in which parts of the fuel system are located.

Furthermore, it is important which type of tank is used, since the different types require different approaches. In this work, type C tanks were used because they are decoupled from the ship’s structure and can be freely placed. Nevertheless, they must comply with the regulations of the IGF Code, which defines specific spaces in the ship. Since type C tanks can be classified as cofferdams, only the tank connections and the surrounding space must comply with the strict regulations.

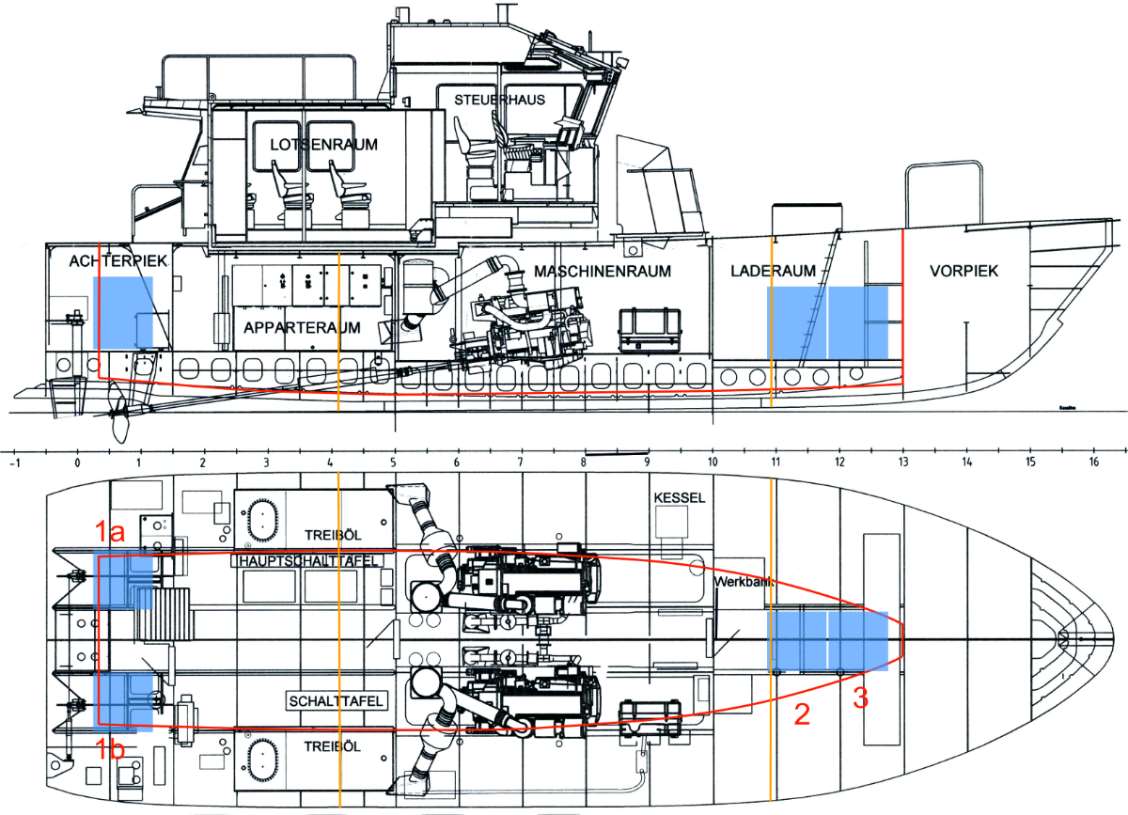

Based on these regulations, a lot of spaces on the vessel cannot be used for additional tanks. Thus, only two spaces can accommodate additional tanks. These are the aft peak and the cargo hold. In consideration of the existing equipment, it was determined that each possible space can accommodate up to two tanks, allowing for four tank positions. Afterwards, it was investigated whether they have an impact on the floating position. The result is that they change the draught by 6 mm when they are full and, in relation to position, cause a change in trim of about 30 mm when full.

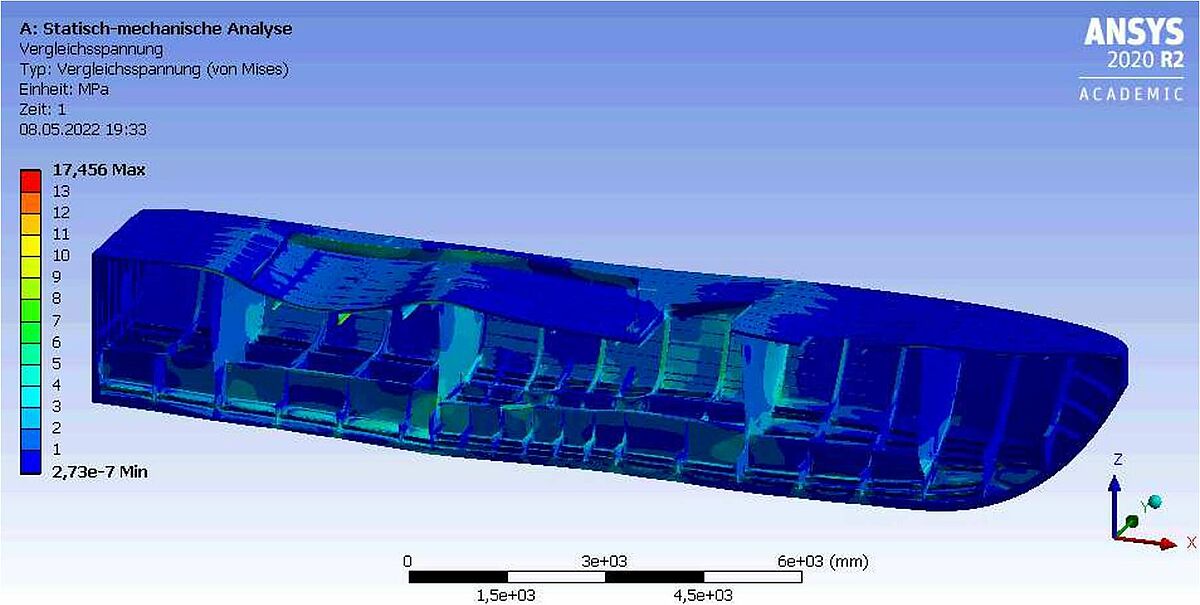

In order to investigate any changes in the structural behaviour of the hull, a static FEA was performed. For this purpose, a highly simplified 3D model was used, which was created based on the technical documentation of the Lotsbetriebsverein e.V. (Kiel branch office). Boundary conditions were then defined, including hydrostatic pressure on the hull, gravitational loading on the entire structure, load cases for the tanks and a load distribution representing the current equipment. The resulting analysis shows that the structural stresses and displacements of the structure are almost negligible compared to the overall ship structure. Even if all four positions contain tanks, only the floating position of the ship experiences a visible change.

Click here to download full article.

Liquid Energy Conference 2022

The Liquid Energy Conference 2022 took place in Rostock at the end of November. It was hosted in the rooms of the Rostock Exhibition Hall, which is located on a former IGA site. This provided a pleasant atmosphere and sufficient space for the conference.

With the topic "Micro- and nanoscale LNG and bio-LNG market - challenges and opportunities", the conference could not have been timelier, in times when new possibilities for energy use are becoming more and more necessary. In addition, the decision to build an LNG terminal in Lubmin has created a potentially important link to create this entirely new market in northern Germany as well. This was not only presented, but also analysed and discussed during this conference.

Click here to read full article

Contact:

Prof. Dr.Eng./Hiroshima Univ. Patrick Kaeding

Dipl.-Ing. Kai Andrich

Funded by:

Interreg South Baltic Programme

European Regional Development Fund

Partners:

- Gdynia Maritime University - Maritime Institute (PL)

- Assoc. for Promotion of Hanseatic Institute for Entrepreneurship and Reg Dev at the University of Rostock (DE)

- Maritime University of Szczecin (PL)

- Metropolitan Area Gdansk-Gdynia-Sopot (PL)

- Association for the Promotion Knowledge about Sea (PL)

- Inwl non-profit Limited Institute for sustainable Economy and Logistics (PL)

- Klaipeda Science and Technology Park (LT)

Website: